4 wheel output

RACECUBE™ Pro Plus: 4Wheel Output and CUBE Vector Output is obtainable

4Wheel Results Output

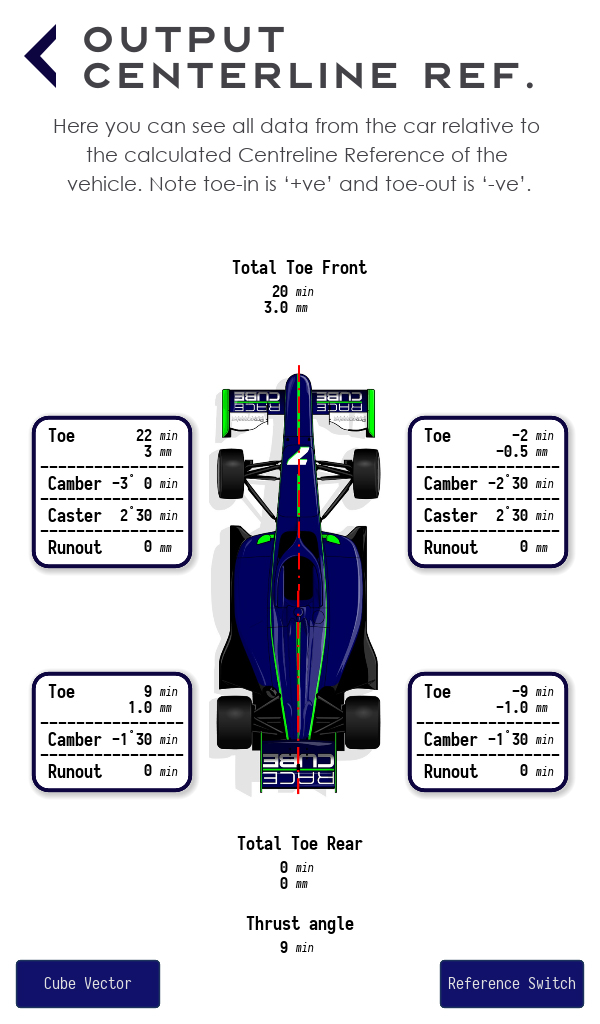

Centreline Reference: Initial Toe Measurement Output

Here you see all data for each respective car wheel relative to the calculated Chassis centreline reference of the vehicle: i.e. Toe and Runout (if measured). As with standard convention, toe-in is ‘+ve’ and toe-out is ‘-ve’.

Thrust angle

Also calculated is the thrust angle; the vehicle's driving direction. If the thrust angle is greater than 10 mins, we recommend using the Toe Adjust (Centreline Ref) function to adjust the rear toe angles to align symmetrically about the Chassis centreline reference, keeping the same total toe angle as calculated or a new one if required. i.e. make the thrust angle coincident with the Chassis centreline reference with equal rear left and right toe angle either side of it. The front toe angles will now need to be adjusted to suit, to prevent the steering wheel from ‘hanging’. Note: as is convention, clockwise is ‘+ve’ thrust angle; anticlockwise is ‘-ve’ thrust angle.

Note that the Chassis centreline reference is not necessarily the same as the Body centreline (Link to Theory tab). The Chassis centreline is determined by the relative positions of all four tyres on the ground, whereas the body centreline is independent and may be skewed to it. Any misalignment can potentially have adverse effects on the vehicle dynamics, aerodynamics and designed elasto-kinematics of the car.

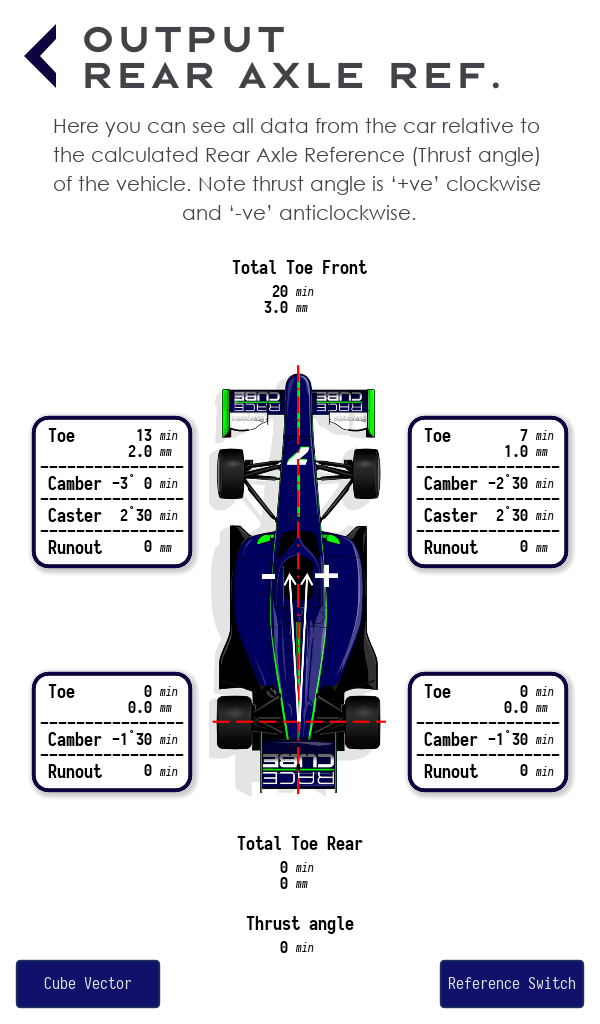

Rear axle reference: initial toe measurement output

Here you see the same calculated data presented relative to the Rear Axle reference or thrust angle. Note the total rear toe angle remains unchanged and the individual rear toe angles are now equal and opposite about the Rear Axle reference or thrust angle direction; now shown as 0°. Toe-in is ‘+ve’ and toe-out is ‘-ve’. The same calculated front toe data from the Chassis centreline reference is now presented as an output relative to the thrust angle.

If the previously calculated thrust angle is less than 10 minutes, it may be acceptable to leave the rear toe angles unadjusted and accept a small misalignment with the Chassis centreline. If so, adjust the front toe angles to the desired values of individual and total toe relative to this Chassis centreline reference. See Toe & Alignment Adjustment and Theory sections. When doing so it is recommended that the steering wheel is centred and locked to ensure it cannot move and is straight relative to the driving direction i.e. the thrust angle direction.

A calculated thrust angle of less than approximately 10 minutes of a degree is unlikely to be noticed by most drivers. However, a professional driver may notice it and comment on it. If this is the case the rear toe angles should be adjusted for zero thrust angle.

Toe adjust: centreline reference

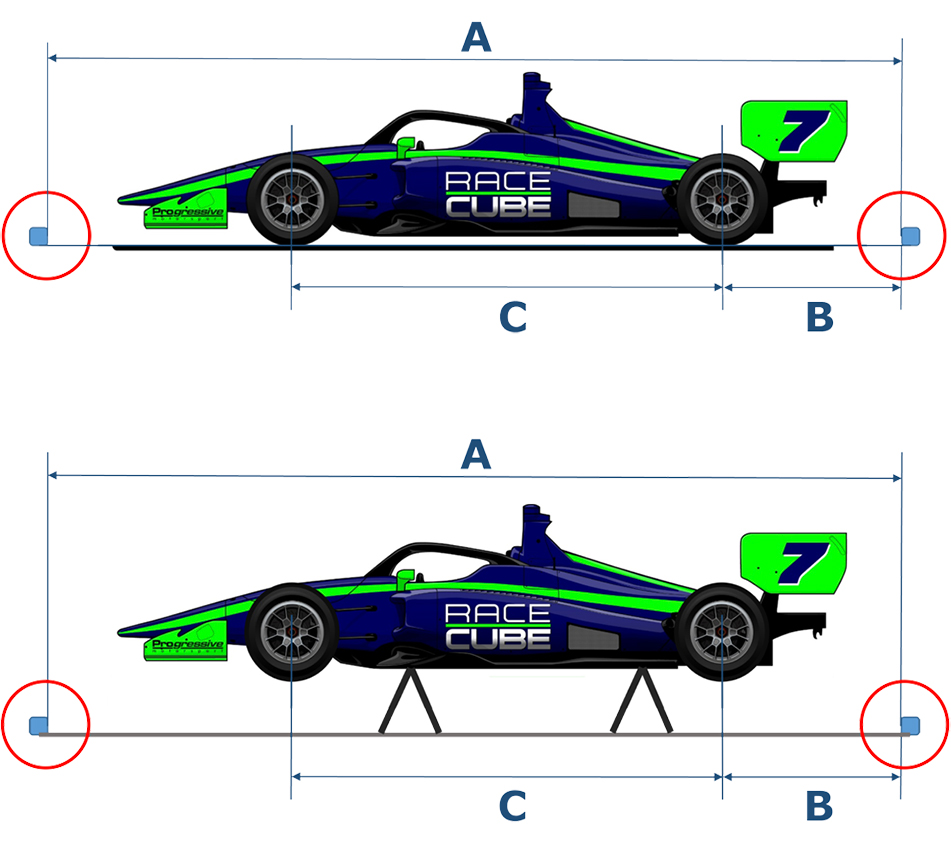

It is important that the front and rear measurement scales are left unmoved from their original positions.

The car can be left on the ground, however IF it is easier for making adjustments, it can be jacked up or put on stands. The magic of the Cube means the car can be on the ground or in the air with the wheels in droop during the whole toe alignment and adjustment procedure. It is also the case that the car can be measured on the ground and then, if it is more convenient, adjusted off the ground. This is because once the car has been measured the software ‘knows’ the relative positions of the wheels and therefore by how much they may need to be adjusted.

To adjust the front wheel toe, first set the steering wheel to be level and locked to ensure it cannot move. Record the Number and Letter where the laser now crosses the REAR bar and then press Calculate to see the new target i.e. where the laser needs to be adjusted to. Then for each FRONT wheel, adjust the vehicle’s track-rods to adjust the toe to the indicated target Number and Letter value that the laser crosses on the REAR measurement scales. Confirm when complete.

To adjust the rear wheel toe, first record the Number and Letter where the laser now crosses the FRONT bar and then press Calculate to see the new target i.e. where the laser needs to be adjusted to. For each rear wheel, adjust the toe-link to the indicated target Number and Letter value that the laser crosses on the FRONT measurement scales. Confirm when complete.

Toe Adjust: Rear Axle Reference

It is important that the front and rear measurement scales are left unmoved from their original positions. If it is easier to do so, the car can be jacked up or put on stands.

On the tablet, enter the FRONT TOTAL toe target value and distance to the scale indicated. Then press Toe Adjust (Rear Axle Ref). To adjust the front wheel toe, first set the steering wheel to be level and locked to ensure it cannot move. Record the Number and Letter where the laser now crosses the REAR bar and then press Calculate to see the new target i.e. where the laser needs to be adjusted to. Then for each FRONT wheel, adjust the vehicle’s track-rods to adjust the toe to the indicated target Number and Letter value that the laser crosses on the REAR measurement scale. Confirm when complete. The front toe angles will now be set relative to the Rear Axle reference i.e. relative to the thrust angle direction.

Set-up recommendations when adjusting toe alignment

Like any other alignment system, it is first necessary to fix the steering rack so that it doesn‘t move when working on the track-rods. Usually this is done by first clamping the steering wheel and setting it to be level in the straight-ahead position.

If you don‘t do this, any force you put into the suspension, when loosening or tightening the nut on the track-rod – or if you touch the tyres - will result in the wheels moving slightly. That is not only true if the car is on the lift-jack or stands but it will also happen when the car is on the ground on its tyres. When you apply torque to the track-rod nuts to tighten them properly, the track-rod will ‘stretch’ marginally and you will see that the toe angle will have changed marginally too (by approximately 2 minutes).

With RACECUBE™, you will see after tightening that the laser has moved slightly on the scale bars. To compensate for this effect, to get the exact target value, we recommend turning the track-rod threads a small amount past (or before) the theoretically exact point (depending on whether the track-rods are in front or behind the axle centre), and then tighten the trak-rod nut. By doing this, the laser will fall back to the optimum target as calculated by the software.

Camber

Camber can be measured separately and saved with the Setup. Attach the Cube to the wheel adaptor and on the screen, press ‘Camber’. Take the reading, record it in the tablet and save it with the Setup.

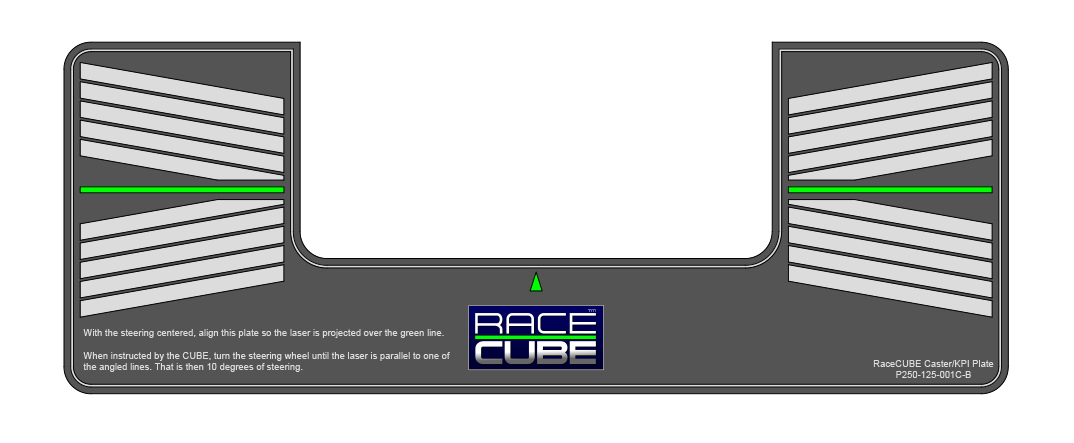

Caster

With the steering centred, align the caster plate so the laser is projected over the green line. Then when instructed by the Cube follow the instructions on the caster plate: turn the steering wheel until the laser is parallel to one of the angled lines. That is then 10 degrees of steering. Then input the results in the tablet. They will be stored with the Setup. [Add Hi -Res Caster plate graphic p8 of A5 booklet]

Note: the greater the accuracy when steering 10 degrees and levelling the bubble, the more precise the caster measurement will be.

King Pin Inclination (KPI)

With the steering centred, align the caster plate so the laser is projected over the green line. Then when instructed by the Cube follow the instructions to read the KPI. Then input the results in the tablet. They will be stored in the Setup.

We want to hear from you!

We welcome all enquiries and are keen to discuss our revolutionary new wheel alignment technology with you. Please get in touch and we'd be delighted to assist.

Call: +44 (0) 7899 961947

Email: info@racecube.uk